Specifications for Custom Printed Stickers

Artwork Guide for your Stickers

Spot Colour Designs

Email us your originated artwork file saved as .eps .ai or .pdf (fully vectorised with text saved to outline to preserve fonts) and colours selected as pantone coated references.

Full Colour Designs

originated artwork file saved as .eps .ai or .pdf with all colours selected as CMYK. We can also use image files for full colour print, saved to a high resolution.

Bleed Off

If your design bleeds off the sticker, please allow 2mm bleed which will be cut off during the trimming/cutting process.

Large Files?

for files too large to email, please send via "sendthisfile" or "dropbox" both are free of charge to use.

No Artwork?

We can prepare a basic layout for you at no extra charge (providing your design is simple and you provide any logo/image in the correct format). More involved layouts may include an artwork fee.

Proofing

We email finalised artwork for approval prior to print production (which is a .pdf viewing file).

Inks and Colour Mixing for Printed Stickers

Inks

Our screen print inks are fully light fast and waterproof.

Our digital inks printed onto vinyl are also fully lightfast and waterproof.

Digital inks for on roll production are not UV stable, so need lamination if you require these for outdoor use.

Spot colour printing

Our inks are mixed to solid colours using the pantone matching system. If you do not have a preferred pantone, we can close-match to your CMYK colour, or mix ink to a swatch of colour posted to us.

Full colour process printing

Computer generated CMYK colours are sent through RIP software directly to our digitgal print machines. Any artwork with pantone or other colour references will be converted to CMYK for print.

Specialty Inks

These include metalic pantone colours, including silver, gold and bronze, along with flourescent and glow in the dark inks.

Sticker Material Guide

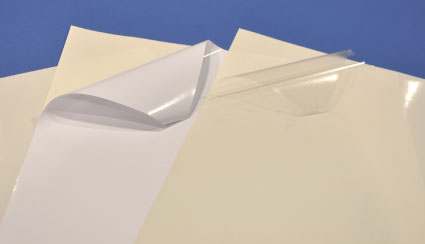

Permanent Self-Adhesive Vinyl

Very durale adhesive and tearproof. Idea for long term use on windows, or outdoor use. Providing the application surface is dry, clean and smooth, your stickers can easily last more than 10 years (even stays put underwater).

Removable Self-Adhesive Vinyl

Durable low-tack adhesive coating. Similar to permanent, but will peel away easier if removed within 6 months of application. Popular for car rear window stickers and retail window stickers.

Static Cling Vinyl

Perfect for windscreen parking permit stickers, charity campaigns and promotions. Self Cling window stickers are easy to remove and transfer between windows without leaving any sticky residue.

High Tack Self-Adhesive Vinyl

Ideal for stickers that need to go onto irregular surfaces requiring high adhesion, including polypropylenes. Due to its aggressive adhesion, HI TACK is great where you need your stickers to be very difficult to remove.

Self-Adhesive Paper

Used for on roll stickers, and available in Permanent, Removable or Hi Tack. We can apply matt or semi gloss varnish or laminate for a professional finish.

Still Unsure? We're always happy to advise, just email or give us a call.

Finishing your Stickers

Individual Stickers

Rectangle and square stickers are guillotined to size as singles. Circles, ovals and any other shapes are either die cut or kiss cut to shape.

Sticker Sheets

Screen printed sticker sheets are kiss cut using a die-kiss cutter on a platen (we have a vast range of cutters in stock).

Digital sticker sheets are print and kiss-cut (no die cutter required).

Stickers on rolls

Stickers on rolls are kiss cut and the waste is removed, making them the best choice if you time is of the essence when using your stickers.